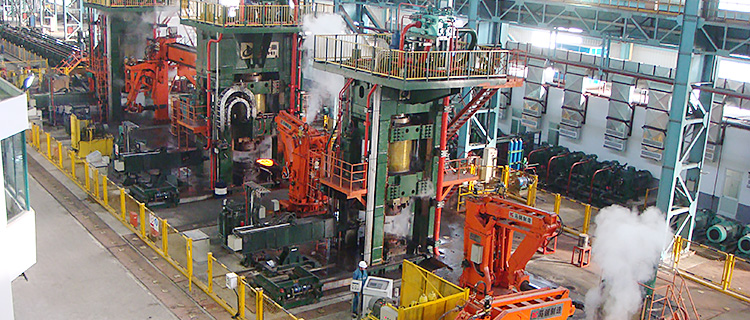

The ZGFZ series servo manipulator is special for casting process, and it is professional mechanical hand for forging industry.

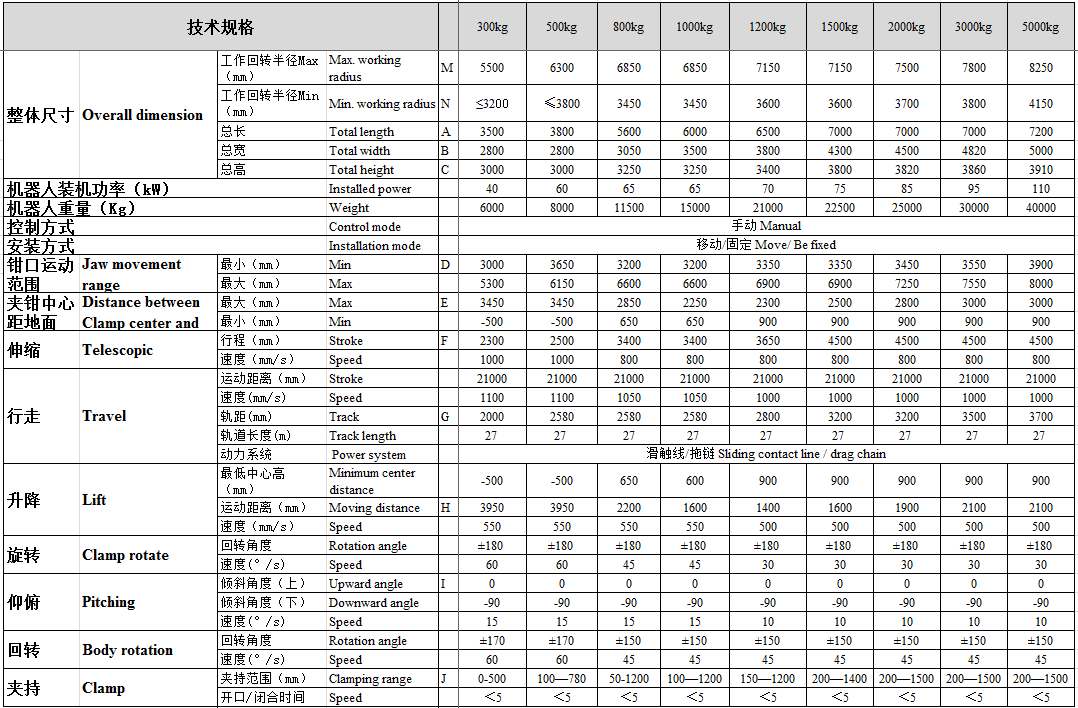

Control mode: manual operation

Series:300kg-5000kg

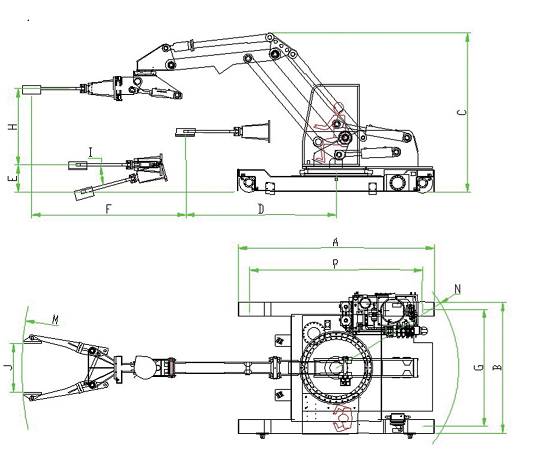

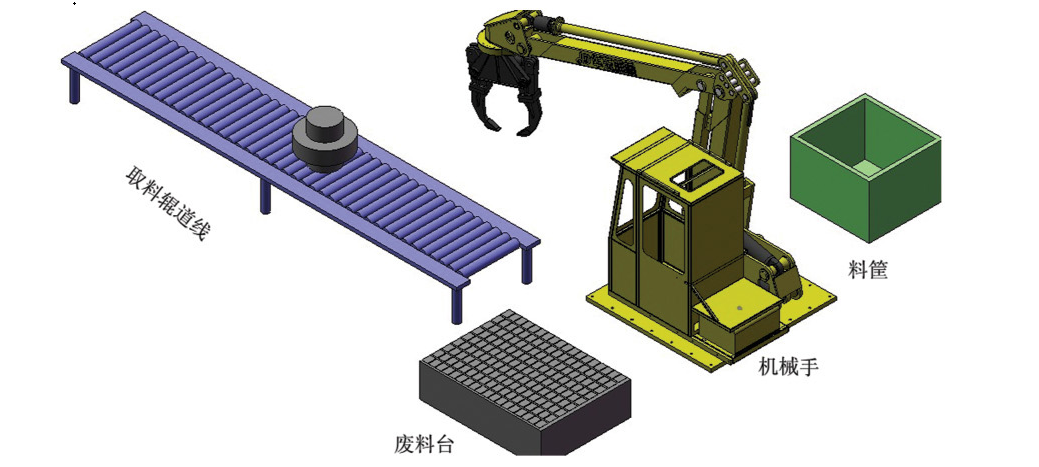

the ZGFZ series servo manipulator is special for casting process, and it is professional mechanical hand for forging industry. It can quickly complete the transmission of various specifications of casting blank between two points, and does not crush the workpiece, such as from the sand bed to the plate conveyor; can also be achieved to quickly transfer the casting workpiece from casting forging press to edge trimmer, from edge trimmer to the machine frame and each station. The servo manipulator can achieve the following actions: body walking, body rotation, lifting clamp, clamp stretch, clamp rotation, clamp back down, clamp swing, clamping.

Technical advantage

Servo response, reduce fatigue

The pressure response system is controlled by a servo motor, The speed of a man's hand is directly proportional to the velocity of the manipulator. Manipulator encounter resistance, there will be pressure response to the operating arm.

The operating handle increases the bearing and reduces the operator's fatigue.

Transmission precision, running without resistance.

Using high precision roller bearing transmission, and keep equipment running longer life span and high stability.

Program calculation, high control accuracy

All the positions of the manipulator are accurately calculated, and the strain gauge is used to test the program to ensure the reliability of the program.

High precision hydraulic system without pollution

Hydraulic tank is made of stainless steel, it is very important for servo valve. No rust, no paint off, avoid servo valve causing problems. And the fuel tank is a positive pressure head, that is, located at the upper part of the pump to reduce the pump wearing.

Compact structure, safe and reliable

The mechanical work arm is long, so it needs reliable torque support. And the frame is protected by three parts:

1) the shock absorber is equipped between the arm and the wrist joint.

2) pressure reduction: detect the angle of the vertical arm, increase or decrease the pressure according to its position. This means that the force of the cylinder is reduced, so that the force acting on the manipulator is reduced, thereby reducing the damage to the equipment.

3) acceleration control: there is this function in this control system, the maximum stress at each acting force on the frame is greatly reduced.