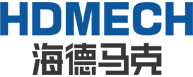

HDMECH is committed to provide solutions for the clients in forging, casting, heat treatment industry, to meet customer demand, its independent research and development, design, manufacture of special robot, achieved automatic handling and precise positioning of the workpiece in the high temperature environment and heavy load situation

Since 2004,HDEMCH has been developed the fourth-generation Robot products. We absorbed international advanced and matured technology experience, taking into account the actual process of domestic manufacturing level, appropriately improved the safety factors-selection. The physical quality and the technical and economic indicators have reached the world advanced level, and with a competitive price and quality.

At 2006, the first manual heavy loads robot was developed successfully, breaking the limiting conditions of high temperature and heavy load in forging industry.

At 2006, the first manual heavy loads robot was developed successfully, breaking the limiting conditions of high temperature and heavy load in forging industry.

At 2007, Through track and wheel design, debugging, the robot can realize the moving function.

In 2008, the first automatic heavy-load robot successfully developed, it can achieve the exact gripping location and positioning accuracy is ± 2 mm

2009, automatic heavy-load robot positioning accuracy was reduced to ± 0.5 mm

2010, robot can be used at manual, semi-automatic and automatic three models to meet different customer needs

2011, robot expanded work load, the maximum can be up to 1200 KG

2013, robot can be used at manual, semi-automatic and fully automatic, and linkage four models, work load can be 5000KG.

This robot can meet casting, forging, heat treatment in special environmental requirements: heavy load, high temperatures and pickup positioning accuracy, has been used in Masteel, Wuxi WTB, CFHI,Dandong-518, and many other well-known domestic enterprises and received very good reputation.

Industrial robot integration focuses on light load, short stroke, hydraulic heavy duty industrial robots under heavy loads (above 500KG), long stroke (3.2m) and intelligentialize, which fill domestic blank, it is the first time for a domestic robot to realize the work situation at heavy load, high temperature, high speed, high precision, intelligent, large stroke situation. The successful application in Masteel, make us to become the domestic leader position in hydraulic heavy duty industrial robots.

Full hydraulic heavy duty robot can alternate artificial to work in bad environment condition. It can achieved high duty work, currently domestic market almost was blank, and there is no domestic competitor, with national intelligent manufacturing 2025 work advancing, the intelligent manufacturing leading the transformation upgrade will become a trend, the robot industrialization can apply to forged hot, nuclear power, and wind power industry.

Product advantages:

have 5 patents for core technologies and software copyright; robot realized to work at situation such as heavy loads, high temperature, high speed, high precision, intelligent, large stroke for first time at Domestic;

Realize the first time clearance-free drive, servo-hydraulic pressure control, man-machine demonstration and remote monitoring and debugging platform