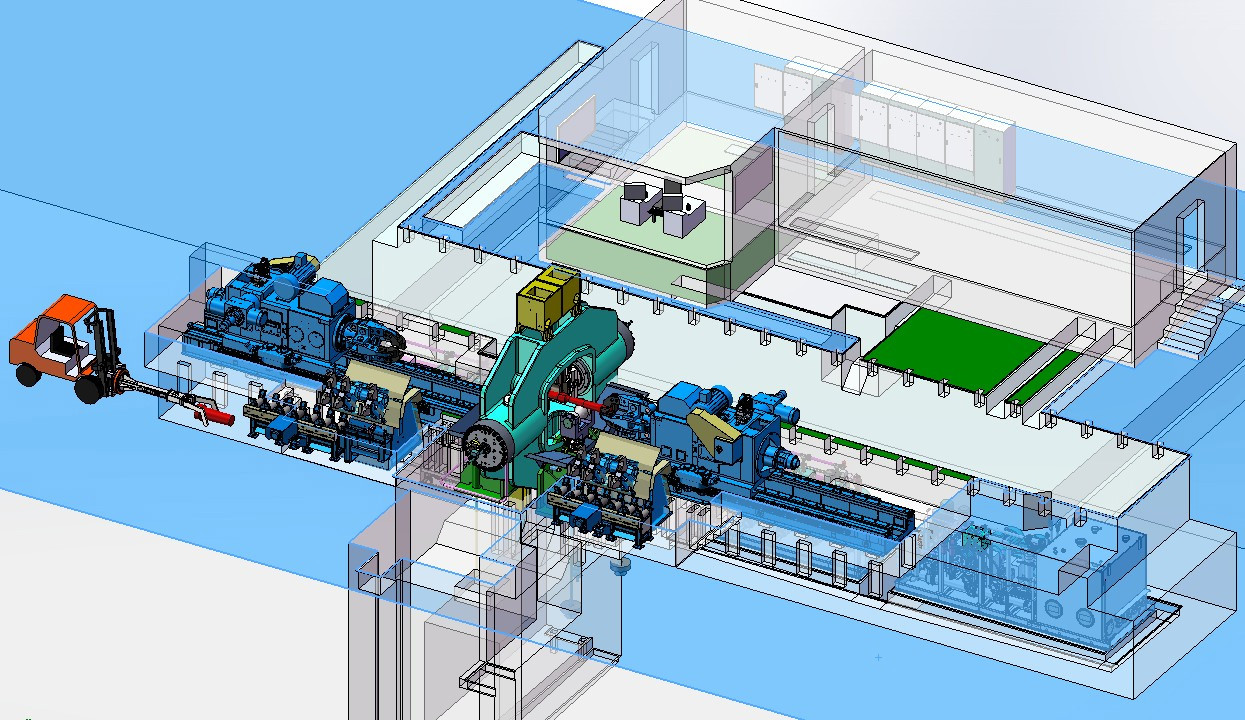

Radial forging machine (the full name of "horizontal radial precision forging machine") is the air hammer forging machine and Quick forging machine replacement products, has obvious advantages in many aspects such as, with its unique four (two) hammer forging principle, the forging material internal and external quality, yield, size precision, automation, the economy and environmental protection and health and safety of operators.

HDMECH rely on many year’s practical experience and technical advantages on design of large Quick forging machine, widely absorbing foreign advanced technologies and innovative design, process optimization, efficient production. In 2012, HDMECH independently developed the radial forging machine HDX/I series, to meet customer needs.

![]()

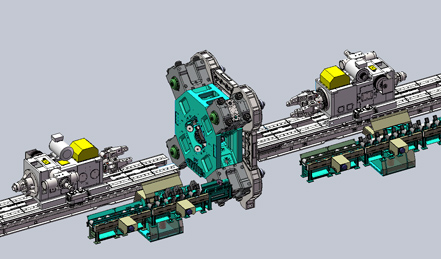

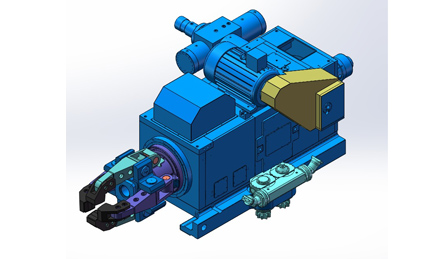

1、Forging machine

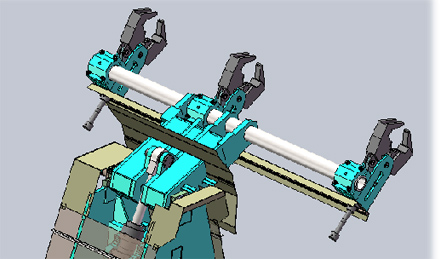

2、Loading manipulator

3、unloading manipulator

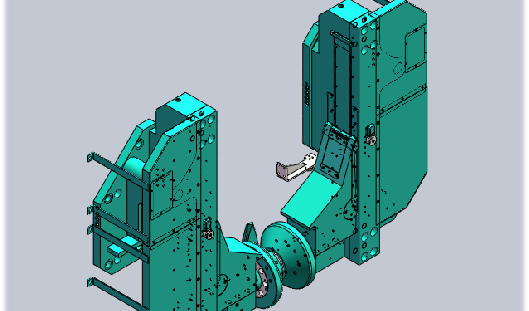

4、Loading device

5、unloading device

6、Guide bed

Application scope

Applicable materials include:

Carbon steels、Stainless steels、Structural steels 、Tool steels、High-speed steels、 Non-magnetic steel、 Nickel-based alloys、Titanium alloys、Super alloys and other special alloys

Listed below are some of the possible forging long products

Bars – round, square and flat

Multi-cranked shafts, for example axles and drive spindles

Thick-walled tubes

Large and medium sized blade blank

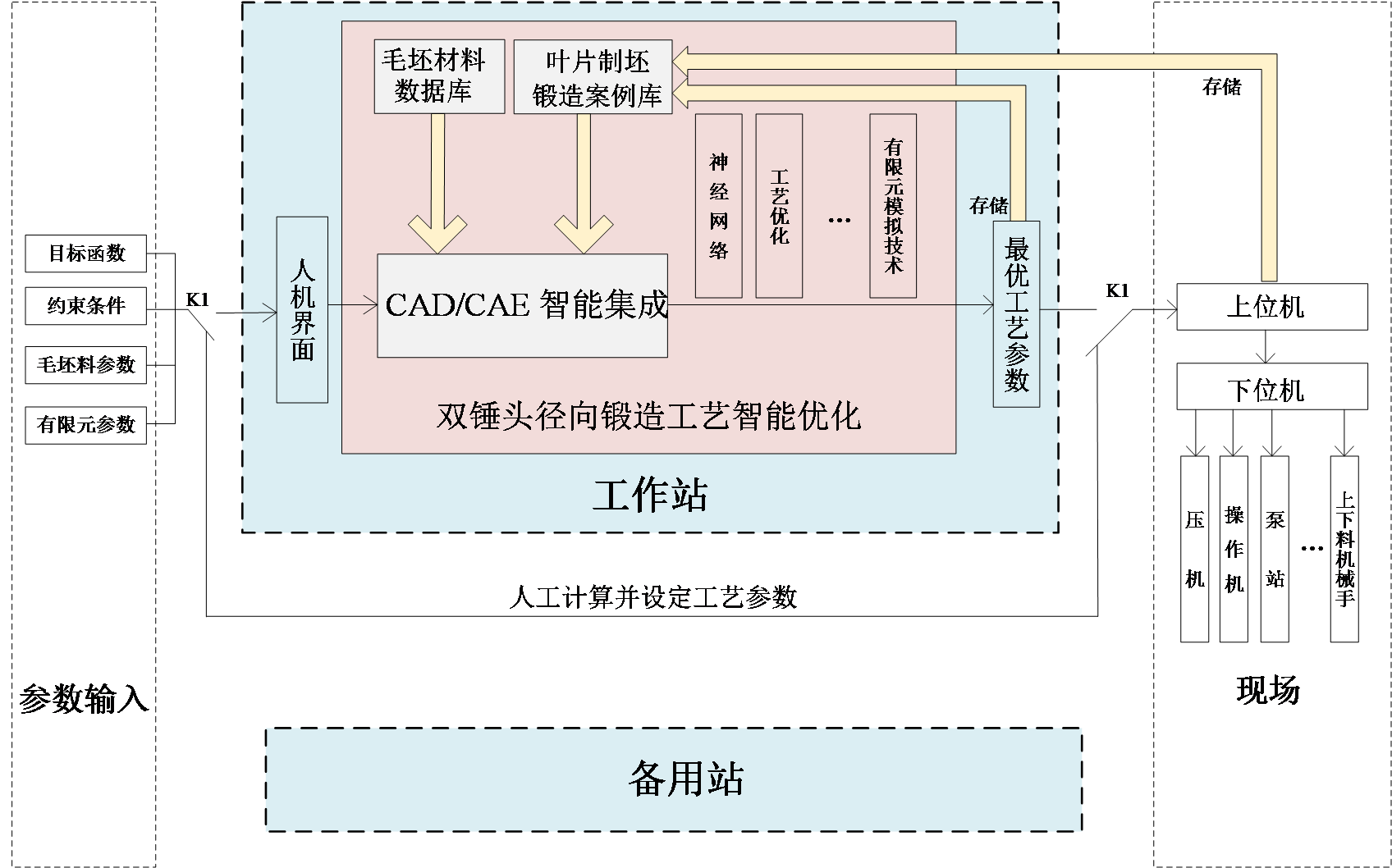

Composition of intelligent optimization system for radial forging process

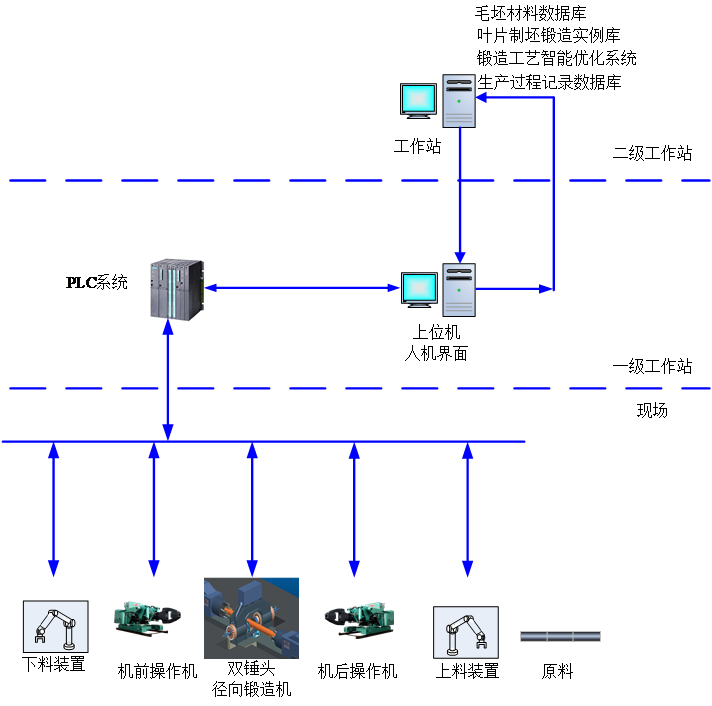

Network structure of intelligent forging process system