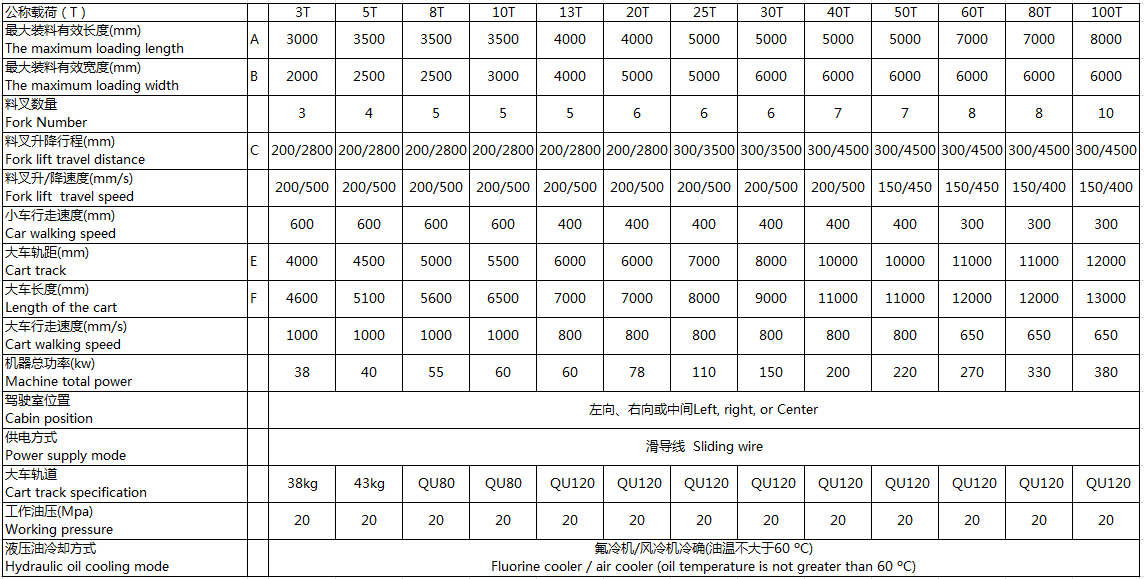

Heat Treatment Manipulator is special reclaimer equipment used for heat treatment production line with the fork structure. It is mainly used for free forging, casting parts, large ring, etc. out or into furnace and quenching. Machine movement is simple, accurate and reliable. The machine can fully realize the mechanical operation of parts heat treatment.

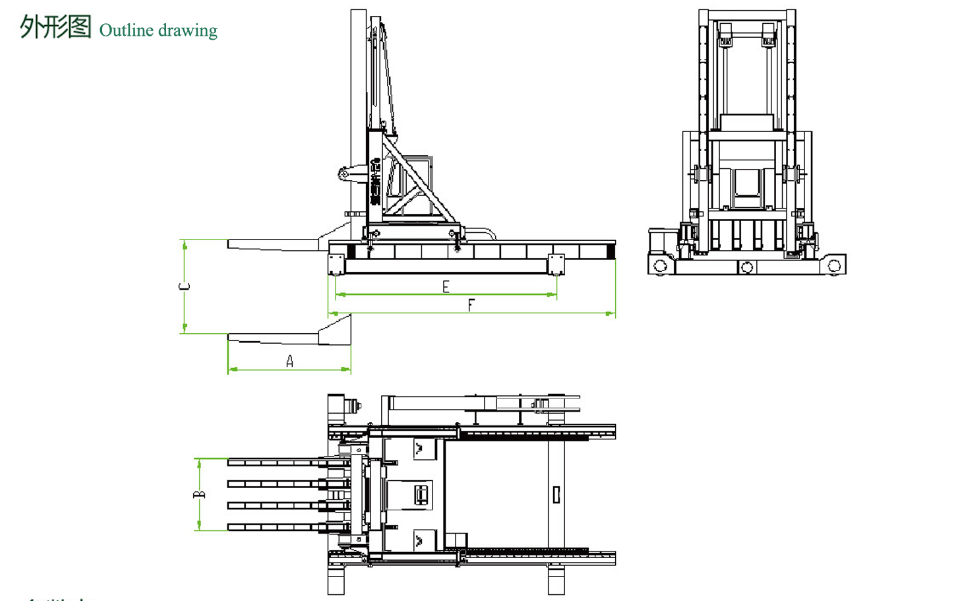

Heat Treatment Manipulator is a fully hydraulic drive and rotary reclaimer equipment with a railroad. According to the movement, it can be divided into two kinds: three degrees of freedom, four degrees of freedom

three degrees of freedom:1、cart walking 2、car walking 3、fork lifting

four degrees of freedom:1、cart walks 2、the car walks 3、 the fork lifts, the platform rotation

1.A high degree of automation, manual operation mode, semi-automatic mode,automatic mode can be realized

2. No oil leakage

To simulate the hydraulic design is reasonable. The hydraulic system is simulated and emulated by AMEsim.

A number of measures to guarantee:

Integration module

Special treatment tank

Unique pipe welding process

Using precision seamless steel tube

Unique pipe joint

3. High speed, high efficiency, constant process time

4.Strong rigidity

Interlock mode

The operating room and the control cabinet are respectively provided with an emergency stop button. (optional)

Manual intervention priority

Equipped with reset button, when suddenly loses power,It can be further jaw inside the furnace dropped out of the furnace door (optional)

5.Safety

6.Comfortable

Automotive air conditioning

Double insulated glass

Isolation seat

Hydraulic control/electric control handle