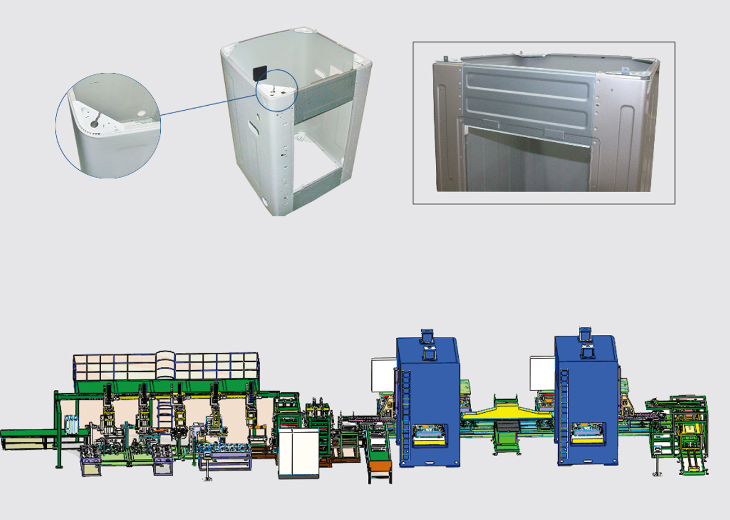

Technical parameter:

External dimension : 35m X 7.6m

Cycle: 15s/piece

Operator Qty:2 guys(lifting ear, connecting plate 1 guy, unloading 1 guy)

Changing model time :5min (one key automatic changing model)

Yield: 99.8%

Loading work station

The feeding station is made up by material stacking trolley, transplanting manipulator, a positioning table and frame ’component etc.

Tow set of material stacking trolley side by side set up in the vertical direction of automatic line,driven by a motor located in tow walking guides below ground level on the working surface, achieving no-stop produce with changing material.

A total of 16 sets of sucker, each of the 2 groups of sucking disc with a vacuum transmitter. Suction location layout is reasonable, to meet a variety of platform party cabinet production. Each sucker is arranged on the filter device, to prevent the damage caused by the suction unclean air.

1# manipulator

1# manipulator main function : the sheet from the positioning platform is transported to the punching station; mechanical hand lifting and transportation are driven by servo motor.

Suckers component is composed of a suction cup, a vacuum generating device, the vacuum suction disc fixing rack, Etc., A total 16 sets of sucker, each of the 2 groups of sucking disc with a vacuum transmitter. Suction location layout is reasonable, to meet a variety of production platform party box. According to the size of the sheet material length ’automatic selection of open, closed vacuum suction cup.

Suction detection: Each mechanical hand set electronic suction detection apparatus, in order to ensure correct grasping manipulator sheet.

Punching and pressing work station

Punching unit consists of 400 tons punch (domestic or foreign well-known brands), punching mold and automatic die changing system:

Type, item | Unit | technical parameters |

400T (custom) | ||

Capacity | kN | 4000 |

Capacity stroke | mm | 10 |

slider stroke | mm | 350 |

Stroke times | time/minute | 18-25*frequency speed governing* |

Max. fixing die height | mm | 750 |

Die set height adjustment | mm | 250 |

Work table size | mm | 1400*2800*200 |

Bottom slider size | mm | 1400*2800 |

the window size | mm | 1420*700 |

The distance between columns | mm | 2900 |

Main motor power | kW | 45 |

Air pressure | MPa | 0.55 |