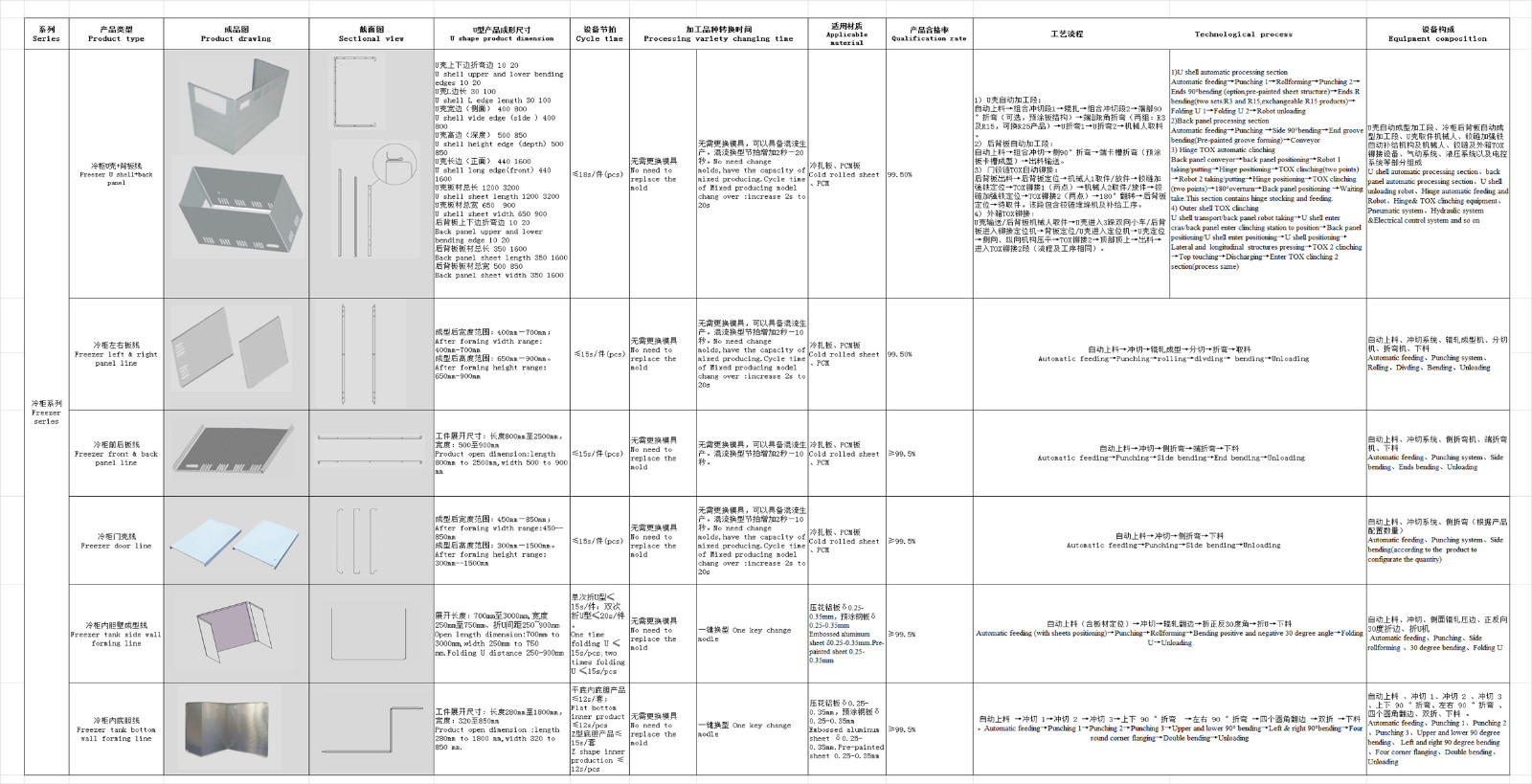

Freezer door forming line adopts more HDMECH's independent technology, sheet metal in the feeding position after the follow-up through the servo robot to complete the processing of sheet metal punching, bending and other processes to achieve the product of flexible production. This production line has some advantages such as good product compatibility, easy operation, convenient mold changing, and high production efficiency, in the touch screen on the recipe settings can be directly transferred to achieve a key for the type.

The whole forming line generally includes: feeding system, punching system, bending system I, bending system II, and bending system III, HDMECH can make the design according to the specific needs of customers.

The production line is for the Hisense Freezer door forming line, the production line cycle time is 12S / piece. The forming line is used to finish the chamfering, punching, stretching and bending of the cabinet, the equipment is stable and the operation is simple.

The forming line is mainly composed of feeding machine, punching system, scribing machine, bending system I, bending system II, bending system ill and supporting pneumatic system, hydraulic system and electric control system and so on. Equipment in the production of products, the length, and width direction can be set according to set parameters (servo drive) for automatic adjustment; data through the touch screen settings and storage, at least to store 50 models

Data, change the type can be automatically adjusted according to model settings.