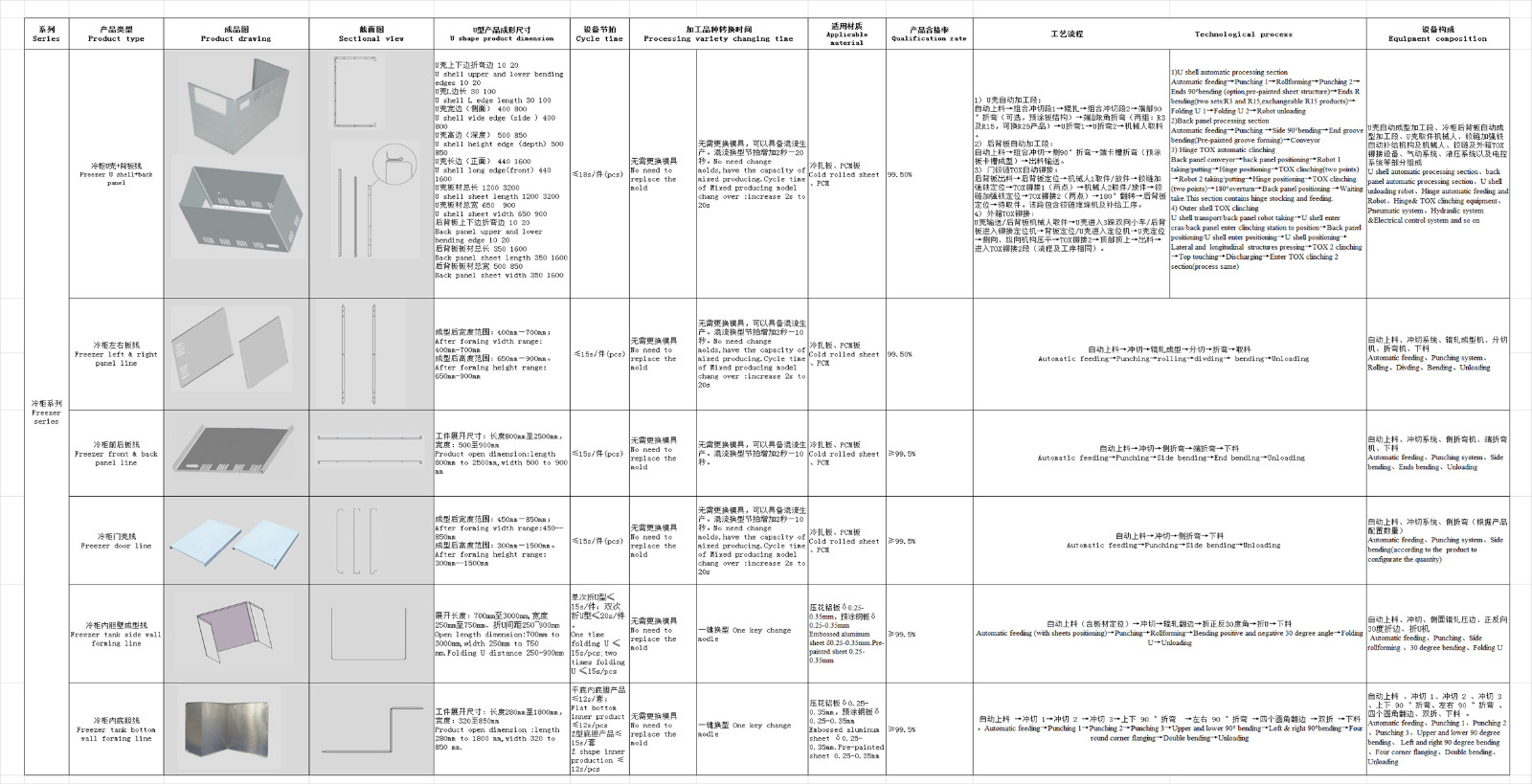

The front and back panels can be collinear production, can also be sub-line production, according to the customer drawings and production needs of the production. Sheet material in the punching and bending process, according to product needs, the conveyor system using a combination of manipulator and belt conveyor design concept to ensure product stability, reliability and compatibility of many varieties of flexible production.

The entire molding line generally includes: feeding positioning system, punching system, side bending machine (or roll forming machine), end bending machine 1, end bending machine 2, end bending machine 3 (end R arc Bending, according to the specific needs of customers, our equipment planning and design.

The equipment for the Xinfei front panel、the back panel forming line, front and back panel of a molding line production, equipment running cycle time 14S / pieces to meet the needs of Xinfei planning capacity. The forming line is used to complete the front and rear panel cutting angle, punching, stretching, bending forming, equipment operation is stable, simple operation, can be achieved one key changing.

The line mainly by the feeding machine, 1 # punching machine, 2 # punching machine, 3 # flanging machine, side bending machine, both ends of the bending machine I, both ends of the bending machine II, both ends of the bend Machine III, unloading and supporting the pneumatic system, hydraulic system and electronic control system and other components.

Equipment in the production of products, the length, width direction can be set according to set parameters (servo drive) for automatic adjustment; data through the touch screen settings and storage, at least to be able to store 50 models of data, change the type can be set automatically Adjustment.