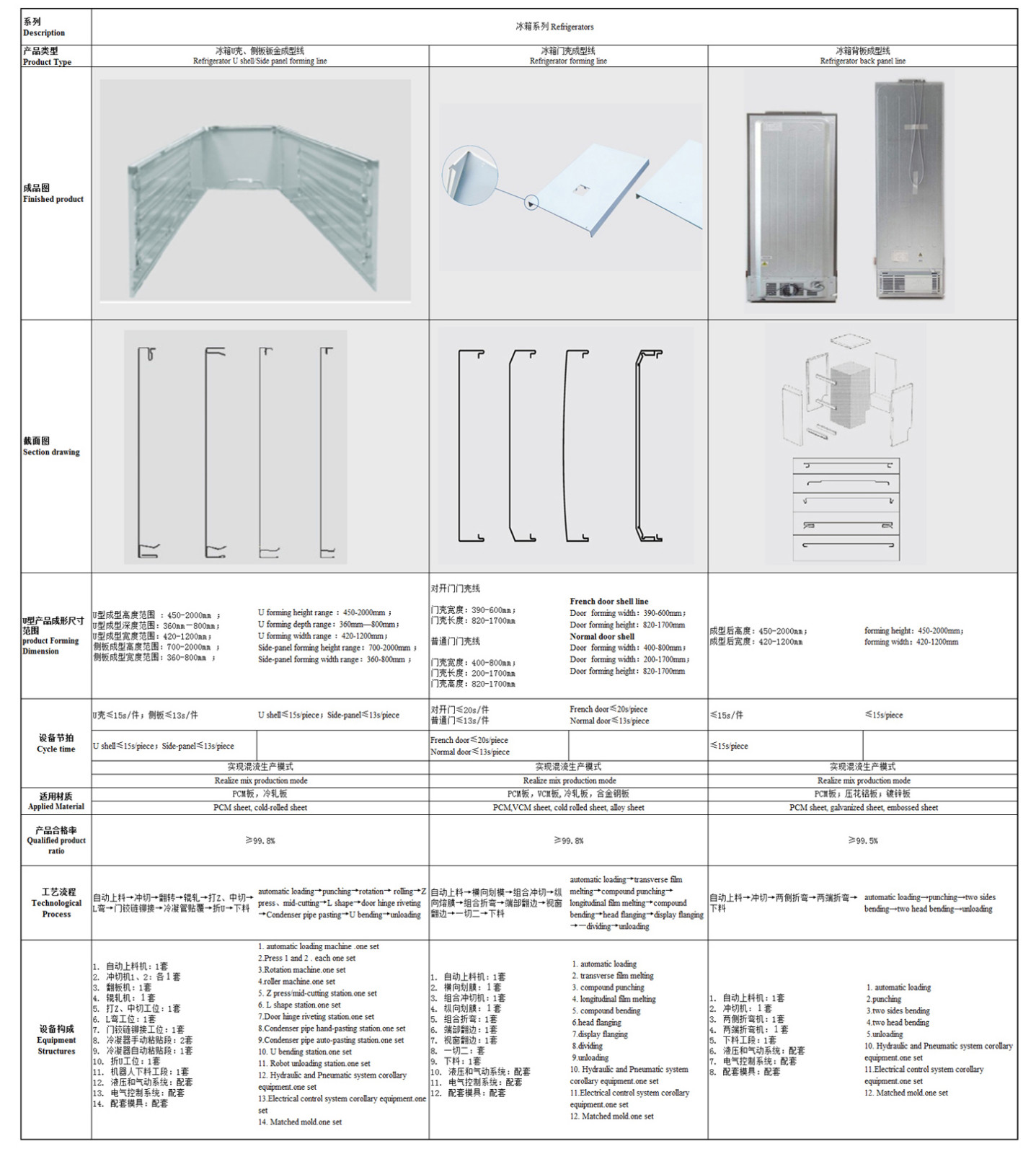

This equipment is used for refrigerator side panel and U shell with customer specified shape and dimension. The applied material can be VCM and PCM, etc, and the finished sheet can be used for next refrigerator assembling after die punching, rolling, condenser pipe pasting, bending and some processes.

Our design and manufactured refrigerator U shell and side panel production line is originated from Japan technology, which keeps us possess high technology advantages in this industry. This production line includes automatic loading, punching, 180︒ rotation, rolling, middle cutting, Z shaping, condenser pipe pasting, U bending, unloading, and corollary equipment such as pneumatic system, hydraulic system and electrical system etc.

The whole production line can satisfy client’s diversified requirement by offering many shape and dimension options. This production line controlled by PlC system, can achieve Non-operators automatic continuous production with cycle time less than 12s for side panel and less than 15s for U shell line, and keep high accuracy degree and the qualified rate can be more than 99.5%.